The heat sinks that used for initial design cannot be used because it cannot reduce the heat that transferred from transistor. The temperature for transistor can be raised up to 100 degree Celsius in 10 seconds. The duration for decorate a cake taken at least 5 minutes above. In addition, the stepper motor cannot run smoothly and produce some noises even the connection at there is perfect.

*Pictures and images will be uploaded soon. Please be patient.

Sunday, May 30, 2010

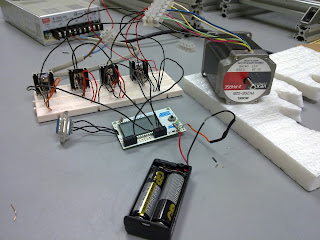

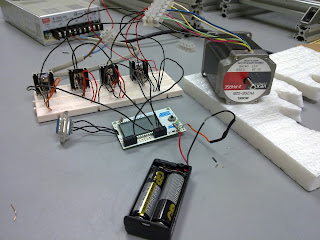

Initial Design for Controlled Circuit

Four of the darling ton transistors (TIP122) are located on the breadboard. A heat sink will be installed at each of the darling ton transistors. The reason for installation because darling ton transistor will produce a lot of heats. Transistor itself cannot stand for too high temperature, so it needs the help of heat sinks, heat can be eliminated. Inductance glue has to be included in between heat sink and transistor. Each of the darling ton transistors got three pins, which are base, collector and emitter. Base connects with the PORTD(s) in the microcontroller, collector connects with the diode (from positive to negative) to the ground port and emitter direct connect to the ground port. 24 V dc power supply will be used to supply the power to energise the coils inside the stepper motor. Each of the stepper motor will have a few of wires. The connection for each wire will be different. For the stepper motor (PK268-02B) that used for initial design, it have four wires which have to connect to collector pin for each transistor and the others two wires will be connected to the power port. PK268-02B has six types of colour wires, which are black, yellow, green, red, white and blue. Yellow and white wire will be connected to the power port while the others will be connected to the collector pin for each transistor. The sequences to connect the wires have to follow the programming that used for run the stepper motor and must be connected correctly.

Saturday, May 22, 2010

Icing Dispenser

The dispenser runs in a simple mechanism.

We uses the coupling concept* in which the spiral metal rod is being spinned by the help of a motor. This spinning action allows the perspex plate to move down and press the syringe in order to make the icing move out . When the switch is changed, the spiral metal rod will be spinning the opposite way and the lowered perspex plate will be lifted up.

The icing dispenser is at all times clamped on top of the xy table and it does not move in any x and y direction.

* coupling is a system whereby two shafts are connected at their ends for the purpose of transmitting power. In this case, the rotating motor transmits power so that the spiral metal rod can spin.

At first, we encountered a problem as the water drips slowly when we did the testing. This problem has to be overcomed as later we are going to substitute cake icing which is much viscous. Consequently, the drawings on the cake will be defeated as the speed of the xy table and the dispenser does not coincide.

As a solution, we used two pieces of perspex to push down the syringe and finally we are successful. Previously, only a piece of perspex is very light and thus it is unable to push the syringe which the syringe stiffness has to be taken into consideration.

We uses the coupling concept* in which the spiral metal rod is being spinned by the help of a motor. This spinning action allows the perspex plate to move down and press the syringe in order to make the icing move out . When the switch is changed, the spiral metal rod will be spinning the opposite way and the lowered perspex plate will be lifted up.

The icing dispenser is at all times clamped on top of the xy table and it does not move in any x and y direction.

* coupling is a system whereby two shafts are connected at their ends for the purpose of transmitting power. In this case, the rotating motor transmits power so that the spiral metal rod can spin.

At first, we encountered a problem as the water drips slowly when we did the testing. This problem has to be overcomed as later we are going to substitute cake icing which is much viscous. Consequently, the drawings on the cake will be defeated as the speed of the xy table and the dispenser does not coincide.

As a solution, we used two pieces of perspex to push down the syringe and finally we are successful. Previously, only a piece of perspex is very light and thus it is unable to push the syringe which the syringe stiffness has to be taken into consideration.

Wednesday, May 19, 2010

Basic Concept

How many times, any of you had observed that how the simple inkjet printer works, how the old typewriter works or how the fax machines works? Well they work on a simple mechanism, known as XY plane movement. Yes! Now you think how?

Lets consider that the ink cartridges moves in X direction and the paper coming out moves in Y direction, so that it obeys XY plane movement principle. Easy but a good example. There are many machines working on the same XY principle in industries, best example is CNC machine.As our cake dresser also needs XY planer movement, so we are going to use XY table principle to build the cake dresser.

The XY table consists of a horizontal and vertical aluminium bar with an icing dispenser . The slide block, made from aluminium will move through the ball screw and create a movement on its axis and so does the topmost bar which will move in the axes of the bottom bar by the moving ball screw.In order to achieve the desired movements , the device has to be installed with a specific programming at both ends of the bars. The Atmel AVR Studio 4 complier has been chosen as the programming for this device.

Sunday, May 16, 2010

Introduction

Have you undergone the situation whereby you suddenly remembered someone's birthday and planned to give that person a cake but you realized that the bakery shop has closed?

Besides that, have you ever think of any method to decorate cakes without using too many decorating utensils and does not involve a lot of mess?

We have the solution!!

We are inventing a device called Electronic Cake Dresser which is able to design cakes.

Besides that, have you ever think of any method to decorate cakes without using too many decorating utensils and does not involve a lot of mess?

We have the solution!!

We are inventing a device called Electronic Cake Dresser which is able to design cakes.

It is a device that is capable to decorate cakes with the help of a particular computer programming. We believed that most of the people have been to a cake shop before. How the workers in the cake shop decorate cakes? They use a manual syringe to decorate them. This method is very time consuming especially for those who are rushing at that time. Now everything has been simplified in which by only pressing some buttons on this device, we will get our desired cake design.

Subscribe to:

Comments (Atom)